CONVEYOR BELTS

- Home / CONVEYOR BELTS

CONVEYOR BELTS

High performance conveyor belts, profiles & types ( - 20°C to 90°C ) 2mm Green, White, Rough top, FDA, PU, PVC, PVC, Jogging Conveyors from 0.8 mm to 5 mm thick, width up to 3000 mm

In almost any food production process, Nitta Polyurethane and PVC conveyor belts can be used. Needless to say that all Nitta food-grade belts meet the requirements of the FDA and the European Union. Some customers require their food-grade belts to be blue, so that non-food particles can be detected. Nitta can offer a complete range of blue Polyurethane and PVC belts for that purpose.

BAKERIES AND CONFECTIONERY INDUSTRY

Bread, pastry, biscuits, sweets, chocolate... You name it! Nitta belts convey them all, in any stage of the process. Transfer problems between conveyors? Our Polyurethane belts are flexible enough to pass the smallest knife edges.

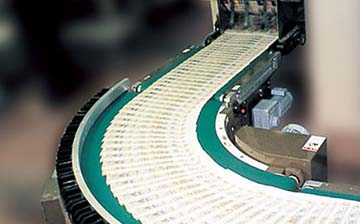

When transporting food products, often accessories are used on our belts such as carriers and corrugated sidewalls. For these processes, the choice of a Nitta belt is a natural one. Also for curved conveyors as shown above, we can serve you with a complete range.

MEAT AND POULTRY

Nitta PVC belts have an excellent oil and grease resistance. Therefore they are widely used in processing plants for meat and poultry products. Although our Polyurethane belts are also very suitable for this industry, mostly a white or blue PVC belt will do. That is, as long as it is a Nitta belt.

| BELT TYPES | TOP COVER | THICKNESS ( MM ) | MIN. PULLY ( MM ) | MIN. °C | MAX. °C | WORKLOAD AT 1% ELONGATION |

|---|---|---|---|---|---|---|

| 1 LRAF 901 / 901 | FABRIC | 1, 6 | 30 | - 10 | + 90 | 9 N / mm |

| 2 LRAFP 02 / G2 | M M 1.4 | PU | 1, 4 | 8 | - 10 | + 80 | 8 N / mm |

| 2 LRAWF 91 | PVC | 2, 5 | 50 | - 10 | + 80 | 9 N / mm |

| 2 LRAWF 912 RB | PVC | 3, 2 | 40 | - 10 | + 80 | 9 N / mm |

| 2 LRAWF 1310 GP | PVC | 2, 8 | 40 | - 10 | + 80 | 9 N / mm |

| 2 LRF 2704 | PVC | 2, 0 | 25 | - 10 | + 80 | 8 N / mm |

| 2 LRF 272 RT 55° | PVC | 6, 0 | 50 | - 10 | + 80 | 8 N / mm |

| 2 LRF 904 M | PVC | 2, 0 | 25 | - 10 | + 80 | 8 N / mm |

| 2 LRAWF 916 WT | PVC | 4, 2 | 50 | - 10 | + 80 | 9 N / mm |

| 2 HRF 2712 | PVC | 2, 8 | 50 | - 10 | + 80 | 12 N / mm |

| 2 NF 906 AS - |M | PVC | 2, 3 | 50 | - 10 | + 80 | 12 N / mm |

| 2 XRFP 02 / PG2 |M M 1.9 | PU | 1, 9 | 20 | - 10 | + 80 | 9 N / mm |

| 3 LRF 271 | PVC | 3, 6 | 100 | - 10 | + 80 | 12 N / mm |

| 3 LRWAF 901 | FABRIC | 3, 0 | 100 | - 10 | + 80 | 12 N / mm |

Conveyor belts for the paper and print industry

Transport equipment and processing machines in the paper and printing industries frequently use transmission belts, such as feeder belts, driving belts and machine tapes. Next to this category of belts, especially at loading/unloading actions and bundling of finished products, conveyor belts are applied.

Nitta has developed a wide range of conveyor belts, specifically for the paper and printing industries as well as a large range of transmission belts. Nitta also developed and supplies an extensive range of conveyor belts for this industry. Many of these conveyor belts have been designed in close cooperation with leading machine builders.

Conveyor belts for the automotive industry & production lines

Interruption or failure of automated conveyor belt production lines can have a big impact on the overall production output. Breakdowns can even lead to substantial losses. Nitta’s high-quality belts reduce downtime, leading to higher productivity and help maximize production capacities.

Nitta has developed a wide range of conveyor belts that can be used in a variety of applications within the automotive industry. Applications include:

PAPER MANUFACTURING & CONVERTING

Nitta provides many different belting options for the various processes throughout paper manufacturing and converting. These include polyamide core skived belts, polyester core quick joint belts, tapes and seamless belts with an array of suitable tooling. Our engineered specifications result in greater performance, longer life, and higher value.

Folder Gluer Applications

Feeder/Infeed, Carrier/Compression, Folding

Corrugated Applications

Bridge, Beater, Scrap, Folding, Counter, Ejector, Stacking, Strapping

Tissue and Towel Applications

Cone Drives, Line Shaft, Back Stands, Unwind/Rewind, Tube Winders / Core Winders

PRINTING & BOOK BINDING

Nitta belts are time-tested and have been proven to outperform the competition. Nitta offers a complete belting solution for the printing industry, including polyamide core skive-splice, finger-splice, conveyor belts, and tools. Nitta belting improves the bottom line for printers with higher running speeds, less downtime, and extended runtime, boosting production and lowering the total cost of ownership.

Nitta belts are used in gravure, web offset, sheetfed and other printing operations as well as book binding and other post-press applications. Applications Include transport, stackers, sheeters, folders, slider tables, trimmers, bookbinding machines, and more. Facility types include:

• Commercial printers

• Publication printers

• Insert advertising printing

• Direct mail printing

• Newspapers

• Business forms printing (check printers)

• Flexible packaging printing (film, foil and paper)

• Saddle-stitching and perfect binding finishing operations (independent of printing firms)